Under what circumstances should molded-case current transformers be taken out of service? How can their burning be prevented?

2022-12-20

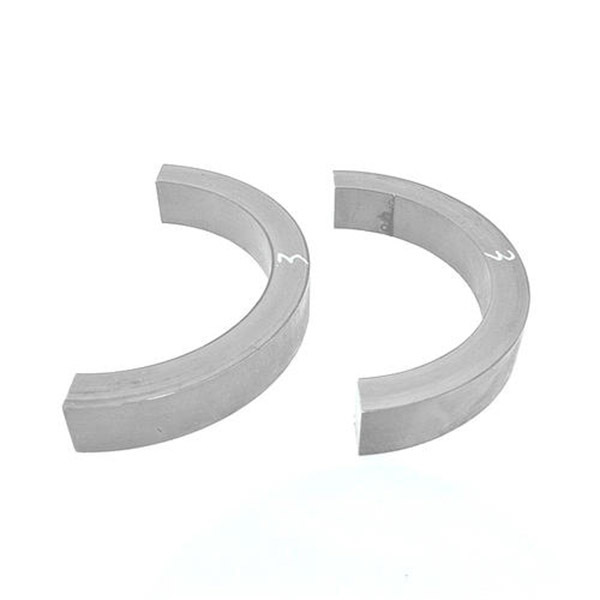

Frequently used in power systems Cast resin current transformer They can be divided into outdoor and indoor types. Their reliability is very important because they measure the voltage and performance of the circuit. Once they fail, it not only easily leads to deviations in measurement results but also brings danger. Therefore, if the following phenomena occur, they should be stopped immediately:

1. The cast resin current transformer is overheating.

2. The high-voltage fuse has blown 2 to 3 times.

3. There is an abnormal noise inside the cast resin current transformer, such as a cracking sound.

4. Glue and oil leakage occurs inside the television or at the lead outlet.

5. The transformer is smoking or has a burnt smell.

6. There is spark discharge between the winding and the casing or between the casing and the ground.

Once a cast resin current transformer malfunctions, it is easy to cause a fire or explosion, so once a malfunction or problem occurs, it should be taken seriously.

Once damage to the high-voltage side insulation of a cast resin current transformer is found, the faulty voltage transformer should be cut off in time using a power circuit breaker, but it should be noted that an isolating switch should never be used. This is because the isolating switch has no arc extinguishing capability, and once used, it can easily lead to busbar short circuits, equipment damage, and danger to operating personnel.

It is impossible to install a switch on the circuit of a cast resin current transformer. When the power supply fails due to the direct disconnection of the fault by the power circuit breaker, the busbar needs to be reversed and the faulty voltage transformer pulled out.

If the transformer smokes or catches fire, immediately pull the busbar power circuit breaker, then pull the isolating switch, and then restore busbar operation.

Although the cast resin current transformer is a small component, it will pose safety hazards if used improperly. Each operator must master the correct usage during operation.

Once a cast resin current transformer is burned out, it is a great loss for both the user and the power company. So how to prevent the cast resin current transformer from being burned out?

First, we need to understand the reasons why the cast resin current transformer is burned out. The reasons are as follows:

Due to the secondary open circuit, a high voltage is generated, and the high voltage causes the transformer to burn out.

If the transformer is used for a long time, the insulation ages, and it is easy to discharge or break down, generating overvoltage, which will also cause the transformer to overheat and burn out.

After the primary side of the transformer is connected to the aluminum bar, the contact surface is heavily oxidized, resulting in a large contact resistance, causing the transformer temperature to rise and leading to burnout.

In addition, if the cast resin current transformer is overloaded, it will burn out.

How to prevent the cast resin current transformer from burning out? The following countermeasures can effectively prevent it. Let's take a look:

Installing a branch circuit breaker can effectively prevent branch faults from affecting the entire feeder power outage. When single-phase grounding is required on the power supply side, it can automatically trip.

Use a metering cast resin current transformer connected behind the circuit breaker, so that once a fault occurs, the circuit breaker can automatically cut off the fault.

Currently, the service life of the sensor is limited, generally 4 years. Users need to check frequently Cast resin current transformer high-voltage insulation testing. If signs of aging appear, replace it with a new one in time.

Regularly clean the primary equipment to reduce dust and oil stains on the product surface and ensure good insulation.

Recommended News

Contact Us