What is the structure and basic characteristics of a Permalloy core?

2022-10-31

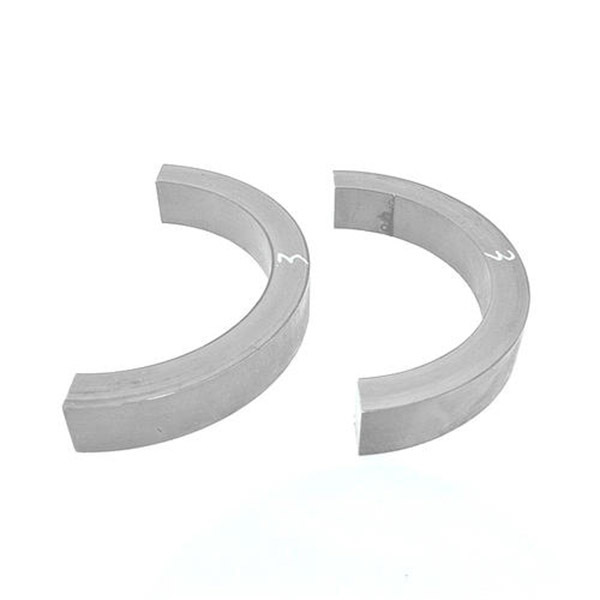

Permalloy core Generally refers to iron-nickel alloy, a widely used soft magnetic alloy. Through appropriate processes, magnetic properties such as initial permeability greater than 105 and high permeability exceeding 106 can be effectively controlled. Coercivity is as low as 2‰ Oersted, and the rectangularity is close to 1 or 0. The face-centered cubic crystal structure of Permalloy has good ductility and can be processed into 1μM ultra-thin strips and various application forms.

I. Structural Characteristics of Permalloy Cores

Permalloy is an iron-nickel alloy with high permeability under weak magnetic fields. Nickel-iron alloys with nickel content greater than 30% have a single-phase face-centered cubic (γ) structure at room temperature, but the single-phase structure near 30% nickel is very unstable, so the actual nickel content of iron-nickel soft magnetic alloys is greater than 36%. When the nickel content in the iron-nickel alloy is close to 75% (atomic fraction), a Ni3Fe long-range ordered transformation occurs in this single-phase alloy, at which point the lattice constant and physical properties (such as resistivity and magnetism) of the alloy will change. Therefore, it is necessary to consider the influence of the ordered transformation on the properties.

II. Basic Characteristics of Permalloy Cores

1. Iron-nickel soft magnetic alloy with high permeability under weak magnetic fields.

2. In order to improve resistivity and process performance, elements such as Mo, Cr, and Cu are usually added to the Fe-Ni binary alloy.

3. Permalloy has excellent soft magnetic properties, with initial permeability μI of 37.5~125mH/m, and high permeability reaching 125~375mH/m; coercivity Hc is 0.8A/m, and resistivity ρ is 60~85μΩ·cm.

4. The alloy is melted in a vacuum induction furnace and formed into cold-rolled strip steel, cold-drawn steel wire, or hot-rolled (forged) plates and bars through cold and hot plastic deformation.

5. Used to manufacture audio transformers, mutual inductors, magnetic amplifiers, magnetic modulators, chokes, audio heads, etc.

Permalloy metal magnetic cores: Various Permalloy materials have different typical magnetic properties, superior to silicon steel materials and ferrites, with higher temperature stability and aging stability.

Permalloy core Mainly used for power collection, energy conversion, electricity measurement, and leakage protection.

Previous:

Recommended News

Contact Us