Some common sense about iron cores, explained by a sensor iron core manufacturer

2022-09-21

Sensor Core The manufacturer believes that traditional amorphous cores are affected by factors such as shearing equipment and strip winding methods. The lap joint structure of the amorphous core is basically 30 laminations per group, and the gap in the corresponding lap joint area is large, resulting in magnetic leakage, which leads to a large no-load current and magnetizing power of the amorphous core, affecting the performance of the transformer.

The sensor core manufacturer believes that traditional amorphous cores are affected by factors such as shearing equipment and strip winding methods. The lap joint structure of the amorphous core is basically 30 laminations per group, and the gap in the corresponding lap joint area is large, resulting in magnetic leakage, which leads to a large no-load current and magnetizing power of the amorphous core, affecting the performance of the transformer. With the market demanding higher requirements for the loss and noise of amorphous alloy transformers, conventional cores can no longer meet the changing situation. Through software upgrades, design optimization, and equipment modifications, a new type of amorphous core with a lap joint structure has been developed. Its main feature is to reduce the number of strips per group, that is, from the original 30 pieces/group to 15 pieces/group, to increase the contact area of the overlapping area, reduce the overlapping gap, reduce the magnetic resistance of the overlapping part of the core, and reduce magnetic leakage during magnetization.

The sensor core manufacturer believes that due to the high hardness and thin thickness of the amorphous alloy strip, and the brittleness of the amorphous alloy after heat treatment, some fragments are inevitably generated during the production, assembly, or use of amorphous alloy transformers. If not controlled, amorphous fragments circulate with the transformer oil's insulation and heat dissipation, which may cause short circuits in the coil, burn out the transformer, and have a great impact on the performance and reliability of the amorphous transformer itself.

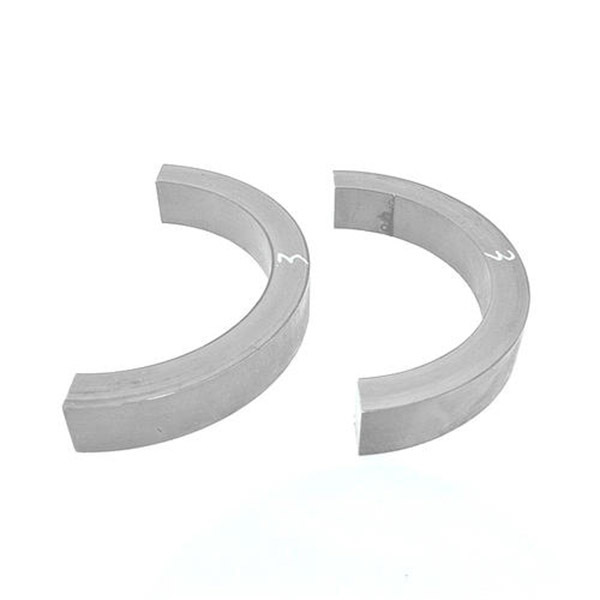

The sensor core manufacturer believes that in order to fix the shape of the amorphous core and prevent amorphous fragments from falling into the transformer coil and causing short-circuit faults, conventional amorphous cores generally have a layer of soft rubber about 1 mm thick applied to both sides. However, due to the weak bonding strength of the soft rubber, after the core is formed and the template is removed, the amorphous round is prone to cracking; at the same time, during transportation, it is easy to deform the core window; during the assembly of the transformer body, because the core is relatively soft, the assembly is difficult, and after the overlapping part of the core is opened, there is a risk of cracking of the core column.

Sensor Core The manufacturer believes that in order to improve the above problems, a new type of end face structure amorphous core has been developed. Epoxy resin and soft rubber are applied to the U-shaped area above the lap joint of the amorphous core to form a hybrid end face structure. The core with a hybrid end face coating structure can enhance the bonding strength between the non-circular pieces, prevent cracking after the template is removed, and at the same time ensure that the core does not deform during transportation, maintaining a good rectangular window, which is conducive to the stability of product performance. At the same time, the thin epoxy resin coating near the core lap joint area ensures the convenience of body assembly and avoids core column cracking, improving the assembly efficiency of the body.

Recommended News

Contact Us